Bright Annealing Furnace Manufacturer in India

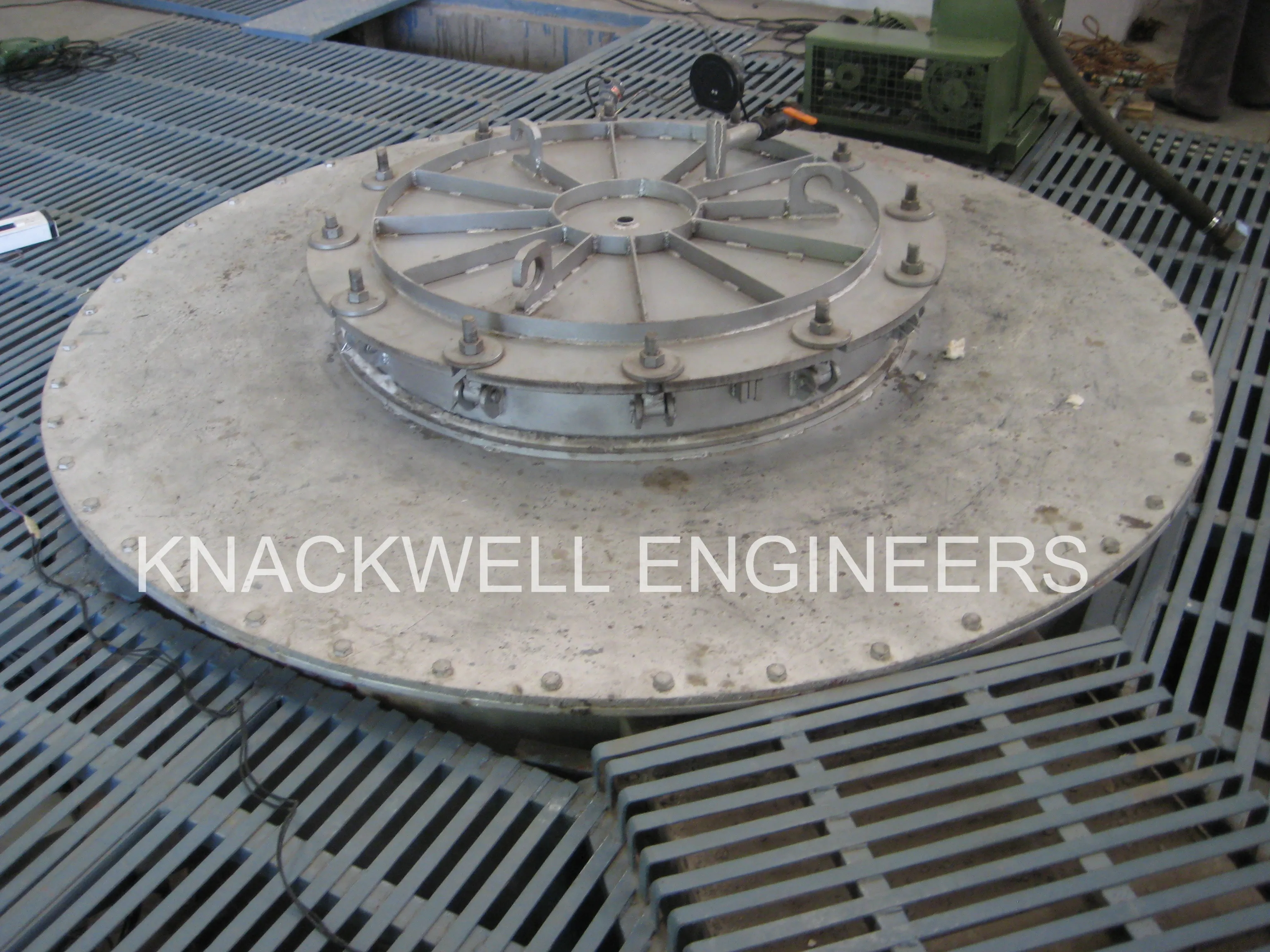

The charging table, entry vestibule, heating portion, cooling section, and exit vestibule make up the furnace system. The furnace was built to fit the tube size, which was determined by the outside diameter and length of the tube.

On a wire mesh conveyor belt, tubes are run through a furnace (muffle type). The conveyor belt speed is variable, and it is modified or regulated according to the size of the tubes.

Coil type heaters are installed on top and bottom of horizontal suspend muffle to provide indirect heating.

The process is carried out in an inert atmosphere (N2) and a reducing environment (CrNH3 - 25% Nitrogen and 75% Hydrogen). The flow of gas is controlled by flow metres mounted on the gas panel, which provide backup safety mechanisms in case of power outages, low gas pressure, and so on.

Contact Knackwell Engineers for bright annealing Furnace installation & application for which furnace is installed or desired.